How to read the reference of an O-ring?

Example:

OR-40X3-NBR90

Where

OR = product type (O-ring or O-ring seal)

40X3 = inside diameter X thickness

NBR = matter

90 = shore hardness

Shore hardness is a material hardness scale, usually between 70 and 90 for O-rings. The higher the number, the harder the material.

What does the number mean at the end of the reference?

This is the indication of shore hardness. Shore hardness is a material hardness scale, usually between 70 and 90 for O-rings. The higher the number, the harder the material.

Difference between NBR, FPM, EPDM, MVQ?

These are the different types of rubber. Each material will be more or less suitable for a use. Refer to the following information: FOR OILS NBR = Nitrile = Butadiene rubber - Acrylonitrile

from -30°C to +120°C FPM = Viton = Fluorinated Rubber

from -20°C to +200°C MVQ = Silicone rubber

from -50°C to +210°C FOR HYDROCARBONS NBR = Nitrile = Butadiene rubber - Acrylonitrile

from -30°C to +120°C FPM = Viton = Fluorinated Rubber

from -20°C to +200°C FOR BRAKE FLUID EPDM = Ethylene Rubber - Propylene - Diene

from -40°C to +150°C FOR WATER EPDM = Ethylene Rubber - Propylene - Diene

from -40°C to +150°C FOR MORE DETAILS ON THE MATERIALS, THEIR STRENGTHS AND LIMITS OF USE, REFER TO THE COMPLETE DESCRIPTION ON THE SEALED SEARCH PAGE

How to choose the size of my O-ring?

An O-ring should not, in general, be too stretched. It is therefore preferable to take a dimension as close as possible to the groove diameter, if applicable.

The tolerances concerning the internal diameter, according to the ISO 3601-1:2008 standard, are determined with the following calculation:

Tolerance ⌀ d1 = ± [(d10,95 x 0.009) + 0.11]

For example, if your inner diameter is 15 mm then the tolerance = ±0.227 mm [(150,95 x 0.009) + 0.11]

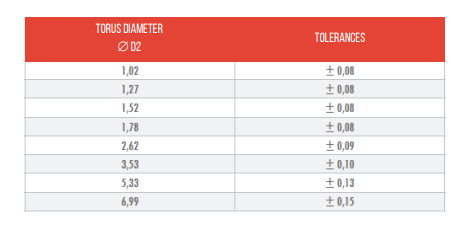

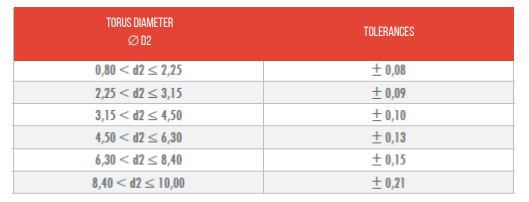

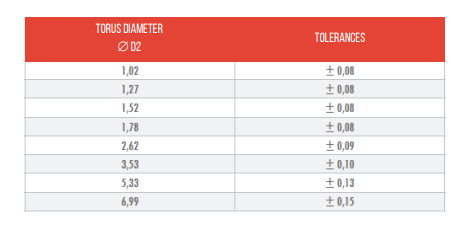

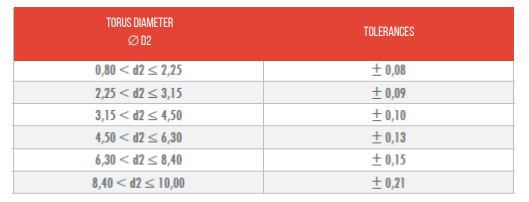

The tolerances concerning the toroid, according to the ISO 3601-1:2008 standard, are as follows:

Standardized torus diameters ⌀ d2

Non-standardized torus diameters ⌀ d2

TIMING BELT PULLEY T2.5 2,5MM

TIMING BELT PULLEY T2.5 2,5MM  TIMING BELT PULLEY T5 5MM

TIMING BELT PULLEY T5 5MM  TIMING BELT PULLEY T10 10MM

TIMING BELT PULLEY T10 10MM  TIMING BELT PULLEY AT5 5MM

TIMING BELT PULLEY AT5 5MM  TIMING BELT PULLEY AT10 10MM

TIMING BELT PULLEY AT10 10MM  TIMING BELT PULLEY 3M 3MM

TIMING BELT PULLEY 3M 3MM  TIMING BELT PULLEY 5M 5MM

TIMING BELT PULLEY 5M 5MM  TIMING BELT PULLEY 8M 8MM

TIMING BELT PULLEY 8M 8MM  TIMING BELT PULLEY 14M 14MM

TIMING BELT PULLEY 14M 14MM  TIMING BELT PULLEY L 9,52MM

TIMING BELT PULLEY L 9,52MM  TIMING BELT PULLEY XL 5,08MM

TIMING BELT PULLEY XL 5,08MM  TIMING BELT PULLEY H 12,7MM

TIMING BELT PULLEY H 12,7MM  DEEP GROOVE BALL BEARING

DEEP GROOVE BALL BEARING  NEEDLE ROLLER BEARING

NEEDLE ROLLER BEARING  ROLLER BEARING

ROLLER BEARING  HOUSED BEARING

HOUSED BEARING  ROD END

ROD END  LINEAR TRANSMISSION

LINEAR TRANSMISSION  OTHER BEARINGS

OTHER BEARINGS  GEARBOX BEARING

GEARBOX BEARING  AGRICULTURAL BEARINGS

AGRICULTURAL BEARINGS  WHEEL BEARING

WHEEL BEARING  SINGLE ROW

SINGLE ROW  DOUBLE ROW

DOUBLE ROW  CERAMIC BEARING

CERAMIC BEARING  THRUST BALL BEARING

THRUST BALL BEARING  SELF ALIGNING BALL BEARING

SELF ALIGNING BALL BEARING  CASTOR BEARING

CASTOR BEARING  HIGH TEMPERATURE

HIGH TEMPERATURE  CAM FOLLOWER

CAM FOLLOWER  TRACK ROLLER

TRACK ROLLER  MAST GUIDE BEARING

MAST GUIDE BEARING  BALL BEARING RETAINER

BALL BEARING RETAINER  DRAWN CUP ROLLER BEARING

DRAWN CUP ROLLER BEARING  NEEDLE ROLLER BEARING

NEEDLE ROLLER BEARING  AXIAL NEEDLE ROLLER

AXIAL NEEDLE ROLLER  INNER RING

INNER RING  NEEDLE ROLLER CAGE

NEEDLE ROLLER CAGE  DRAWN CUP ROLLER CLUTCHES

DRAWN CUP ROLLER CLUTCHES  TAPERED ROLLER BEARING

TAPERED ROLLER BEARING  ROLLER BEARING

ROLLER BEARING  YOKE TYPE TRACK ROLLER

YOKE TYPE TRACK ROLLER  SPHERICAL ROLLER BEARING

SPHERICAL ROLLER BEARING  THRUST ROLLER BEARING

THRUST ROLLER BEARING  ROLLER BEARING CAGE

ROLLER BEARING CAGE  RAW CONE

RAW CONE  RAW CUP

RAW CUP  HOUSED BEARING 0 BOLT

HOUSED BEARING 0 BOLT  HOUSED BEARING 1 BOLT

HOUSED BEARING 1 BOLT  HOUSED BEARING 2 BOLTS

HOUSED BEARING 2 BOLTS  HOUSED BEARING 3 BOLTS

HOUSED BEARING 3 BOLTS  HOUSED BEARING 4 BOLTS

HOUSED BEARING 4 BOLTS  HOUSED BEARING ACCESSORIES

HOUSED BEARING ACCESSORIES  TSM ROD END

TSM ROD END  TSF ROD END

TSF ROD END  GE ROD END

GE ROD END  DIN ROD END

DIN ROD END  GEG ROD END

GEG ROD END  SQ ROD END

SQ ROD END  SA ROD END

SA ROD END  SSR ROD END

SSR ROD END  SI ROD END

SI ROD END  GEEW ROD END

GEEW ROD END  SQZ ROD END

SQZ ROD END  TPN ROD END

TPN ROD END  TAC ROD END

TAC ROD END  SQL ROD END

SQL ROD END  GEK ROD END

GEK ROD END  PHS ROD END

PHS ROD END  GEZ ROD END

GEZ ROD END  GEEM ROD END

GEEM ROD END  TAPR ROD END

TAPR ROD END  GAC ROD END

GAC ROD END  GX ROD END

GX ROD END  OTHER ROD ENDS

OTHER ROD ENDS  LINEAR BEARING

LINEAR BEARING  SEAL

SEAL  SEALING ACCESSORIES

SEALING ACCESSORIES  O-RING SEAL

O-RING SEAL  ROTARY SHAFT SEAL

ROTARY SHAFT SEAL  HYDRAULIC SEAL

HYDRAULIC SEAL  V-RING SEAL

V-RING SEAL  X-RING SEAL

X-RING SEAL  SEALING WASHER

SEALING WASHER  WIPER SEAL

WIPER SEAL  ROPE SEAL

ROPE SEAL  VK EC END COVER

VK EC END COVER  NILOS SEALS

NILOS SEALS  OTHER SEALS

OTHER SEALS  PISTON SEAL

PISTON SEAL  PNEUMATIC SEAL

PNEUMATIC SEAL  SEAL ASSORTMENT

SEAL ASSORTMENT  AUTOMOTIVE SEAL

AUTOMOTIVE SEAL  PTFE SEAL

PTFE SEAL  BACK-UP RING

BACK-UP RING  SPEEDI-SLEEVE

SPEEDI-SLEEVE  BELT

BELT  ROLLER CHAIN

ROLLER CHAIN  SPROCKET

SPROCKET  TAPER BUSHING

TAPER BUSHING  V-GROOVED PULLEY

V-GROOVED PULLEY  TIMING BELT PULLEY

TIMING BELT PULLEY  RACK & SPUR GEAR

RACK & SPUR GEAR  RIBBED BELT PULLEY

RIBBED BELT PULLEY  V-BELT

V-BELT  RAW EDGE COGGED V-BELT

RAW EDGE COGGED V-BELT  TOOTHED BELT

TOOTHED BELT  POLY-V BELT

POLY-V BELT  HEXAGONAL BELT

HEXAGONAL BELT  VARIATOR BELT

VARIATOR BELT  BELT ACCESSORIES

BELT ACCESSORIES  SIMPLEX

SIMPLEX  DUPLEX

DUPLEX  TRIPLEX

TRIPLEX  CONNECTING LINK

CONNECTING LINK  OFFSET LINK

OFFSET LINK  SIMPLEX SPROCKET

SIMPLEX SPROCKET  DUPLEX SPROCKET

DUPLEX SPROCKET  TRIPLEX SPROCKET

TRIPLEX SPROCKET  IDLER SPROCKET

IDLER SPROCKET  V-GROOVED PULLEY SPA

V-GROOVED PULLEY SPA  V-GROOVED PULLEY SPB

V-GROOVED PULLEY SPB  V-GROOVED PULLEY SPC

V-GROOVED PULLEY SPC  V-GROOVED PULLEY SPZ

V-GROOVED PULLEY SPZ  SPUR GEAR

SPUR GEAR  GEAR RACK

GEAR RACK  RIBBED BELT PULLEY PL

RIBBED BELT PULLEY PL  RIBBED BELT PULLEY PJ

RIBBED BELT PULLEY PJ  LUBRICANT

LUBRICANT  ADHESIVE

ADHESIVE  PENETRANT

PENETRANT  LUBRICANT

LUBRICANT  GREASE

GREASE  DEGREASER

DEGREASER  CLEANER

CLEANER  THREADLOCKER

THREADLOCKER  GLUE

GLUE  ADHESIVE

ADHESIVE  GASKET SEALER

GASKET SEALER  GASKET SEALING

GASKET SEALING  CYLINDRICAL BUSHES

CYLINDRICAL BUSHES  RETAINING RING

RETAINING RING  BALLS AND NEEDLES

BALLS AND NEEDLES  WASHER

WASHER  TOOLS

TOOLS  ANTI VIBRATION

ANTI VIBRATION  LOCK NUT

LOCK NUT  ADAPTER SLEEVE

ADAPTER SLEEVE  PAP BUSHES

PAP BUSHES  FLANGED BUSH PAF

FLANGED BUSH PAF  BRONZE BUSHES WITH COLLAR

BRONZE BUSHES WITH COLLAR  BRONZE BUSHES

BRONZE BUSHES  EXTERNAL RETAINING RING

EXTERNAL RETAINING RING  INTERNAL RETAINING RING

INTERNAL RETAINING RING  E-CLIP

E-CLIP  CIRCLIP PLIERS

CIRCLIP PLIERS  NEEDLE

NEEDLE  BALLS

BALLS  BALL BEARING RETAINER

BALL BEARING RETAINER  THRUST WASHER

THRUST WASHER  LOCK WASHER

LOCK WASHER  WAVE SPRING WASHER

WAVE SPRING WASHER  COMPRESSION WAVE SPRING WASHER

COMPRESSION WAVE SPRING WASHER  MULTIWAVE COMPRESSION SPRINGS

MULTIWAVE COMPRESSION SPRINGS  OVERLAP WAVE SPRING WASHER

OVERLAP WAVE SPRING WASHER  CURVED SPRING WASHER

CURVED SPRING WASHER  SPRING DISC DIN2093

SPRING DISC DIN2093  FINGER SPRING WASHER

FINGER SPRING WASHER  SPLIT WAVE SPRING WASHER

SPLIT WAVE SPRING WASHER  WAVE SPRING ROUND WIRE

WAVE SPRING ROUND WIRE  CIRCLIP PLIERS

CIRCLIP PLIERS  DIMENSIONAL MEASUREMENT

DIMENSIONAL MEASUREMENT  MOUNTING - DISMOUNTING

MOUNTING - DISMOUNTING  GREASE - LUBRICATION

GREASE - LUBRICATION  ALIGNMENT - INSPECTION

ALIGNMENT - INSPECTION  MM ANTI-VIBRATION

MM ANTI-VIBRATION  MF ANTI-VIBRATION

MF ANTI-VIBRATION  PM ANTI-VIBRATION

PM ANTI-VIBRATION  FF ANTI-VIBRATION

FF ANTI-VIBRATION  PF ANTI-VIBRATION

PF ANTI-VIBRATION  ANTI-VIBRATION MACHINE BASE

ANTI-VIBRATION MACHINE BASE  PMP ANTI-VIBRATION

PMP ANTI-VIBRATION  ANTI VIBRATION DIABOLOS

ANTI VIBRATION DIABOLOS  PFP ANTI-VIBRATION

PFP ANTI-VIBRATION